We offer a wide range of products to meet your processing needs. From the steel to the high reflective aluminum, brass, copper etc. we can offer the diverse solutions to meet your needs.

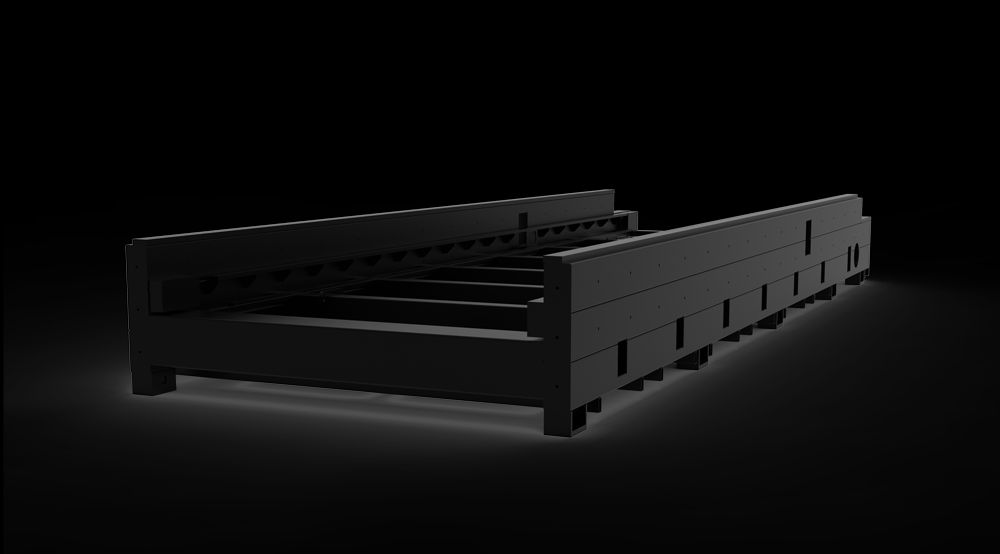

We manufacture the bed in our own factory, and the bed quality can make sure the stability, we control the quality by ourself.

All the main parts can be customized by your needs.

Life-term service. 24 hours online service and life-term service with factory price even out of warranty.

Model | SPARK-3015 | SPARK-4020 | SPARK-6020 | SPARK-12025 |

Laser power | 1000-6000 W | 1000-6000 W | 1000-6000 W | 1000-6000 W |

Table size | 3000*1500 | 4000*2000 | 6000*2000 | 12000*2500 |

Max. Positioning speed | 120 | 120 | 120 | 120 |

Positioning precision | ± 0.03 | ± 0.03 | ± 0.03 | ± 0.03 |

Repeated positioning precision | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

X/Y Axis Max. AC speed | 1.5G | 1.5G | 1.5G | 1.5G |

NO. | Item | Brand | Noted |

1 | Working body | REMCOR | Welding body |

2 | IPC computer (Win 7 ) | REMCOR | China |

3 | Water chiller | Domestic | China |

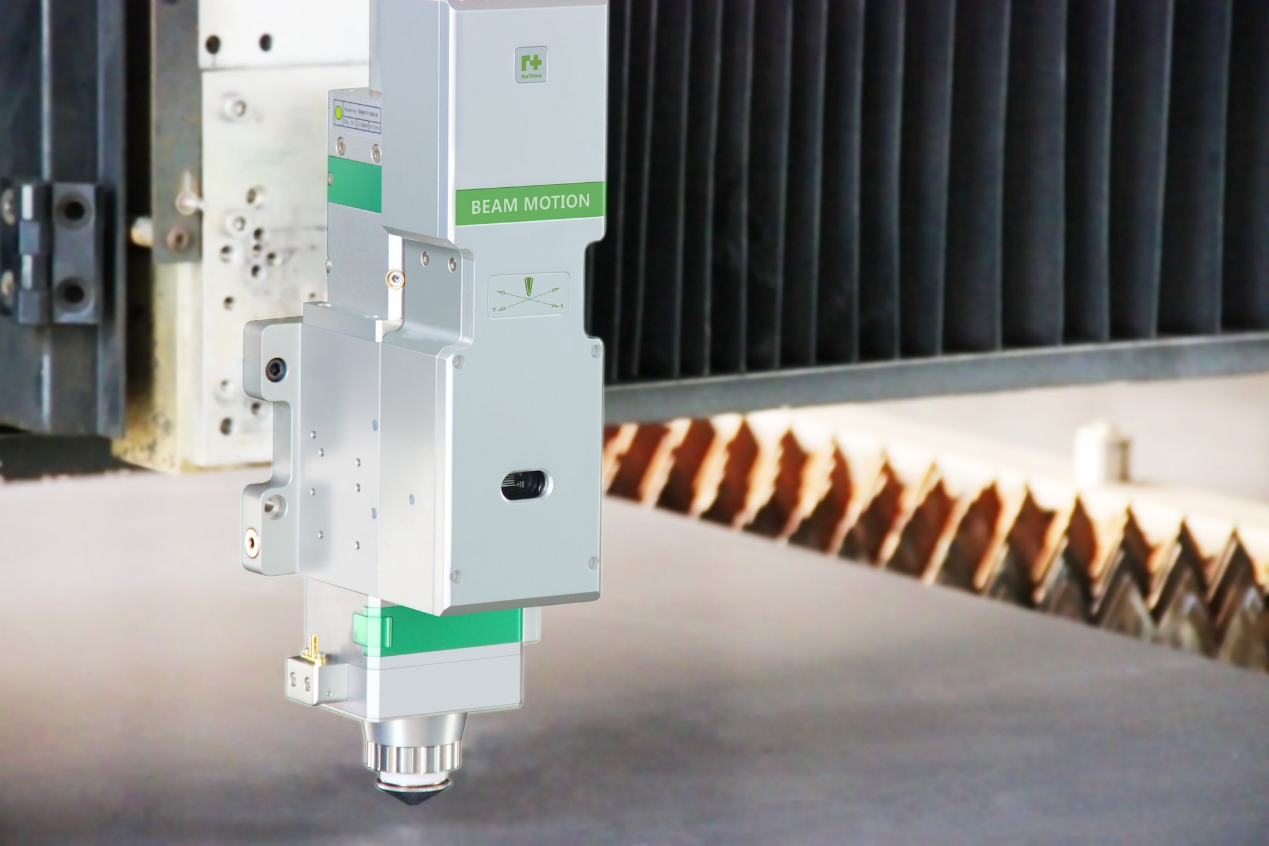

4 | Automatic height adjuster | Raytools auto | Switzerland |

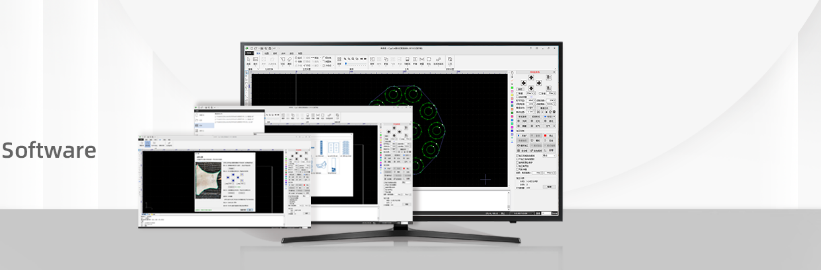

5 | Control system | Cypcut | China |

6 | Reducer | MOTOREDUCER | France |

7 | Laser source | MAX/ Raycus / IPG | China |

8 | Laser head | Raytools | Switzerland |

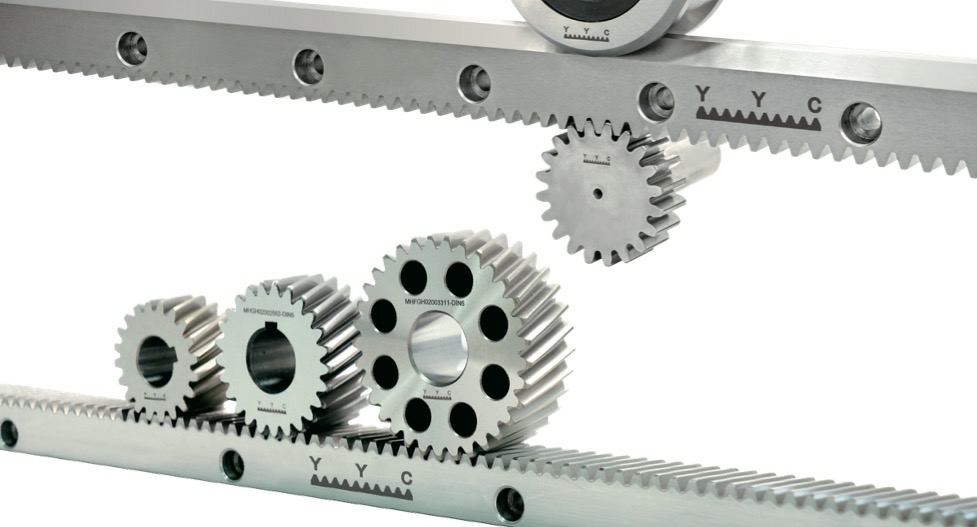

9 | Rack, gear | YYC | Taiwan |

10 | Guide | HIWIN | Taiwan |

11 | X,Y,Z axis servo motor | Fuji | Japan |

12 | Electrical components | Imported | Imported |

13 | Pneumatic Components | SMC | Japan |

14 | Exhaust fan | REMCOR | China |

15 | Independent control cabinet | REMCOR | China |

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time.

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Adopts Japanese Yaskawa motor, Taiwan HIWIN guide and YYC rack gear, French motor reducer. The positioning accuracy of the machine tool is 0.03 and repositioning accuracy can be 0.01.

Do not hesitate to give us a call or drop off a message if you have any question.