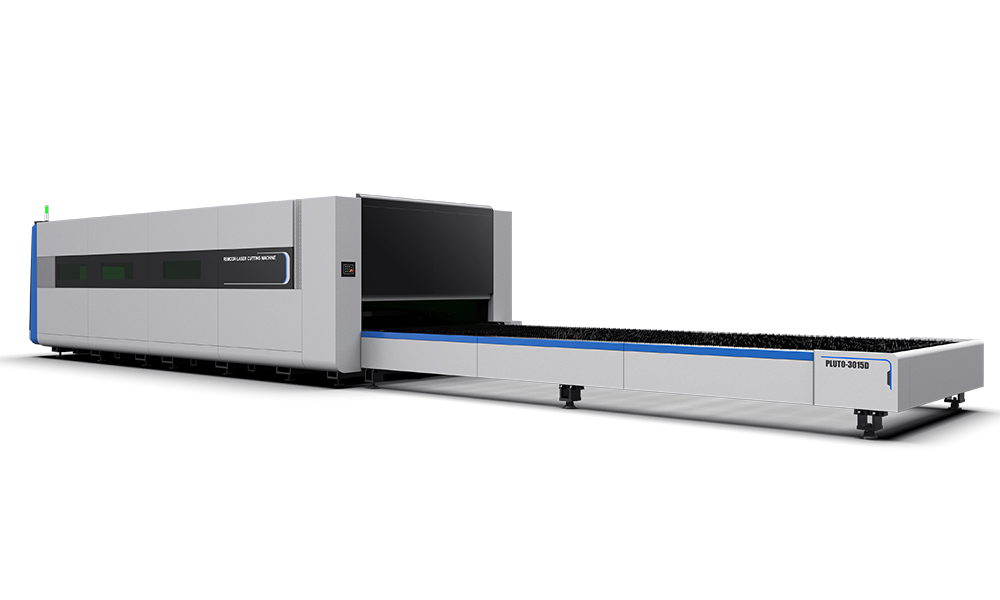

SHOCKING CUTTING SPEED. The Pluto UD series laser cutting machine can realize the shock cutting performance. Second piercing, smooth cutting lines, beautiful shiny cutting finish. The cutting speed efficiency for 20kw increased by 200-500% compared with 6kw.

Excellent cutting quality, It's easy to get beautiful cutting finish without debugging again and again compared with 6kw, especially for medium and thick plates.

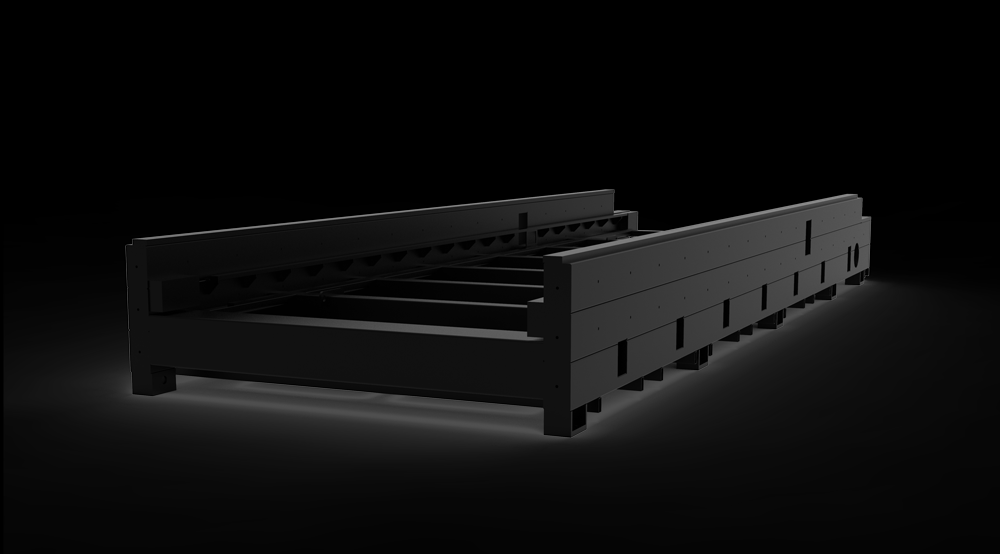

Durable use bed and superior configurations. We adhere the bed is the most important because the other parts maybe have the chance to change with the development of the technology, but once bed lose precision, it's a huge waste. So, for our PLUTO UD series, we apply with the fully-plate welding bed, and annealing treatment to release the tense. Which ensure the durability. Moreover, a lot of professional inspection tools to ensure the precision.

PLUTO-Parameters | ||||

Model | PLUTO-3015D | PLUTO-4020D | PLUTO-6020D | PLUTO-12025D |

Laser power | 1000-15000 W | 1000-15000 W | 1000-15000 W | 1000-15000 W |

Table size | 3000*1500 | 4000*2000 | 6000*2000 | 12000*2500 |

Max. positioning speed | 120 | 120 | 120 | 120 |

Positioning precision | ± 0.03 | ± 0.03 | ± 0.03 | ± 0.03 |

Repeated positioning precision | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

X/Y axis max. AC speed | 1.5G | 1.5G | 1.5G | 1.5G |

Fully-plate welding bed and annealing stress removal undergo over 600⁰, can stand with high acceleration. The strength, rigidity and stability are guaranteed.

Strong brick was applied to transfer the heat. Efficiently prevent the machine bed from being deformed by the heat and guarantee the service life.

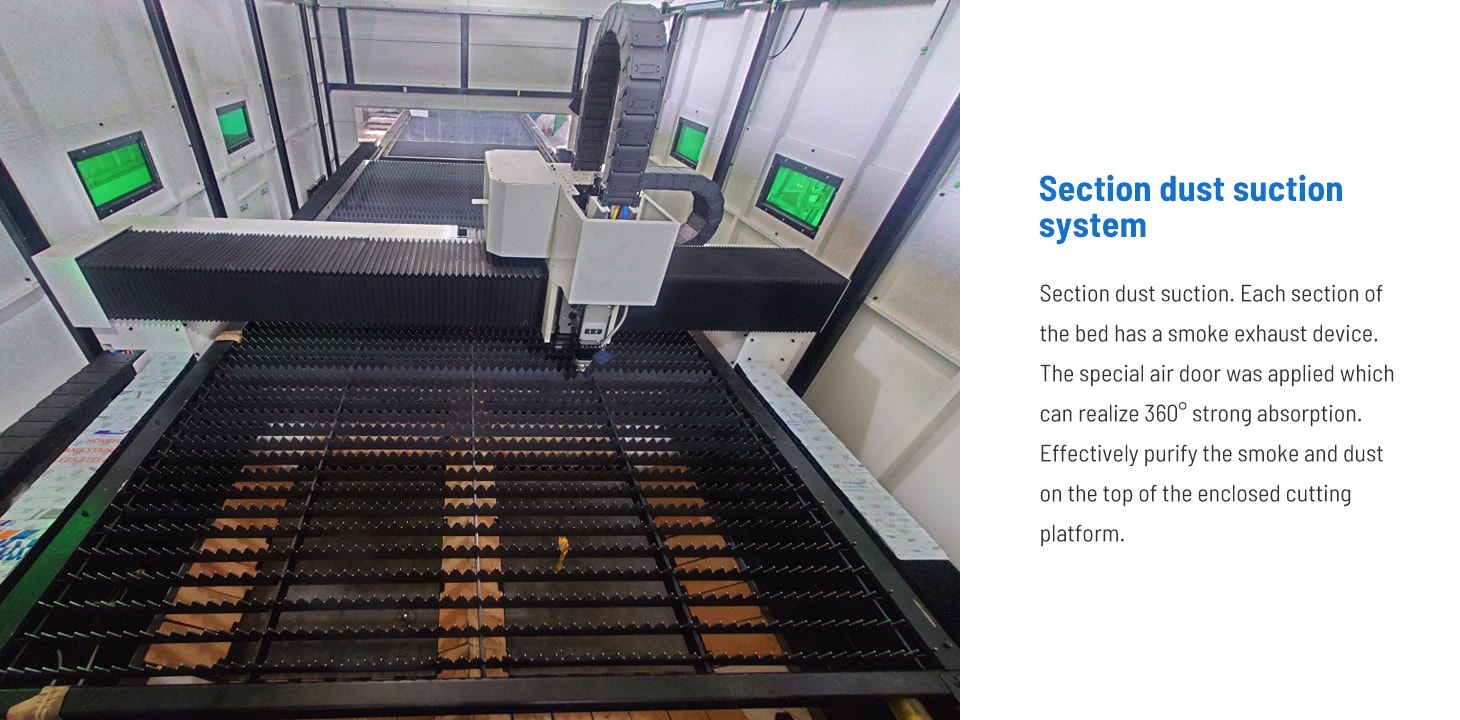

Inter-switching workbench, exchange fast in 19 second, saving the loading time

Smarter and safer

Built-in multiple sets of sensors, real-time closed-loop intelligent monitoring, rapid diagnosis of problems and proactive warning.

The anti-collision design of the cutting head effectively reduces the depot-repar probability, without technical support, customers can replace the broken parts by themselves, and the maintenance cost is lower

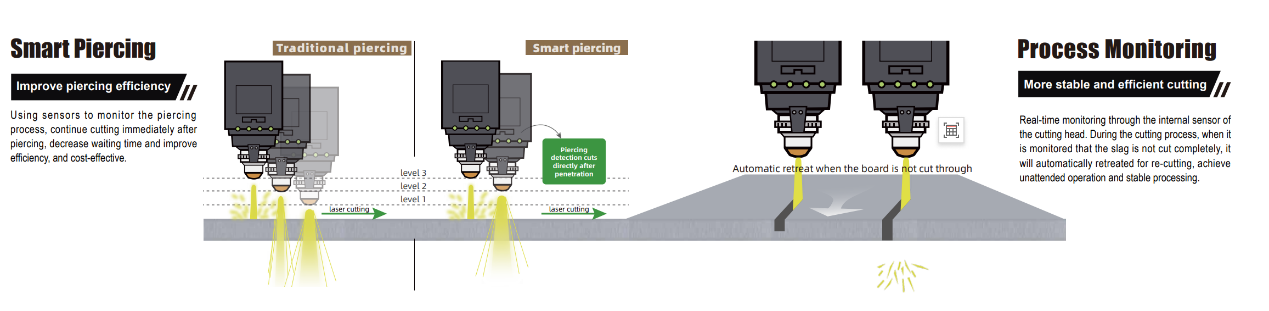

Improve piercing efficiency

Using sensors to monitor the piercing process, continue cutting immediately after piercing, decrease waiting time and improve efficiency, and cost-effective.

More stable and efficient cutting

Real-time monitoring through the internal sensor of the cutting head. During the cutting process, when it is monitored that the slag is not cut completely, it will automatically retreated for re-cutting, achieve unattended operation and stable processing.

Do not hesitate to give us a call or drop off a message if you have any question.