Flexible, Suitable for cutting a wide range of materials, including highly-reflective metals and medium or high thickness mild steel.

Reliable. Fully quality insurance system from the bed manufacturing and installation. Fully-tested and reliable thanks to 18 years of experience in machine manufacturing.

Fast speed cutting and beautiful Performance. Fiber laser cutting can accurately complete complex cutting with good edge quality. Can create components with precision tolerances in a fast, clean, and effective way.

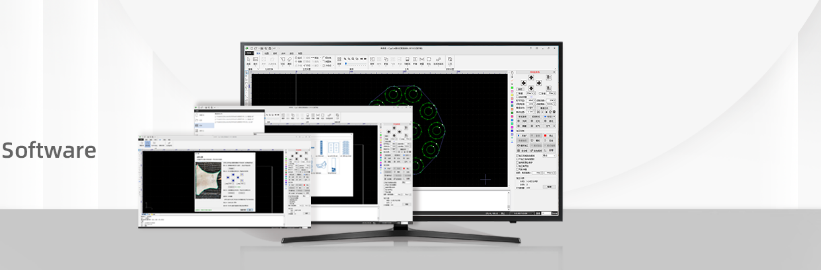

User Friendly. Convenient operation thanks to the friendly Cypcut CNC system. Maximizing yield and reducing material waste.

PLUTO-Parameters | ||||

Model | PLUTO-3015D | PLUTO-4020D | PLUTO-6020D | PLUTO-12025D |

Laser power | 1000-15000 W | 1000-15000 W | 1000-15000 W | 1000-15000 W |

Table size | 3000*1500 | 4000*2000 | 6000*2000 | 12000*2500 |

Max. positioning speed | 120 | 120 | 120 | 120 |

Positioning precision | ± 0.03 | ± 0.03 | ± 0.03 | ± 0.03 |

Repeated positioning precision | ± 0.01 | ± 0.01 | ± 0.01 | ± 0.01 |

X/Y axis max. AC speed | 1.5G | 1.5G | 1.5G | 1.5G |

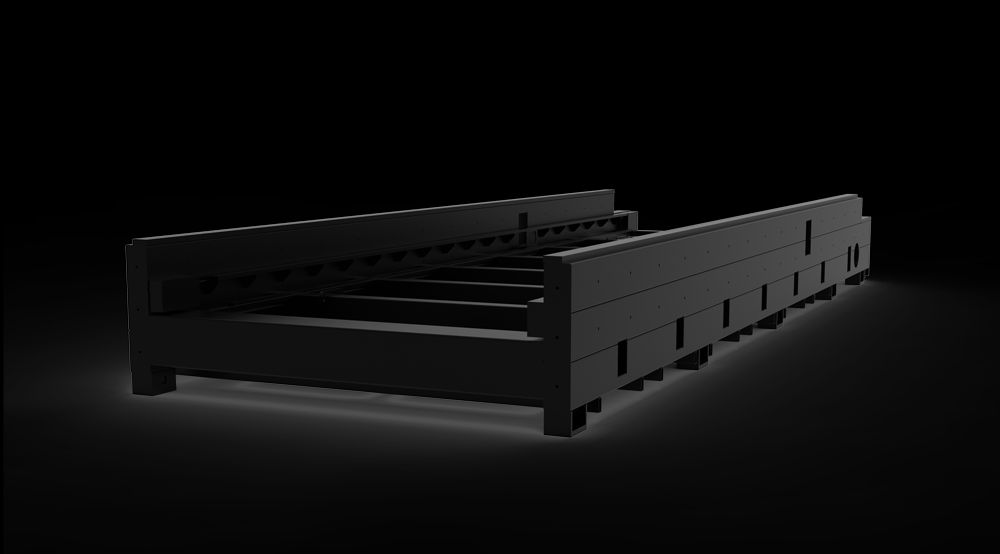

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time.

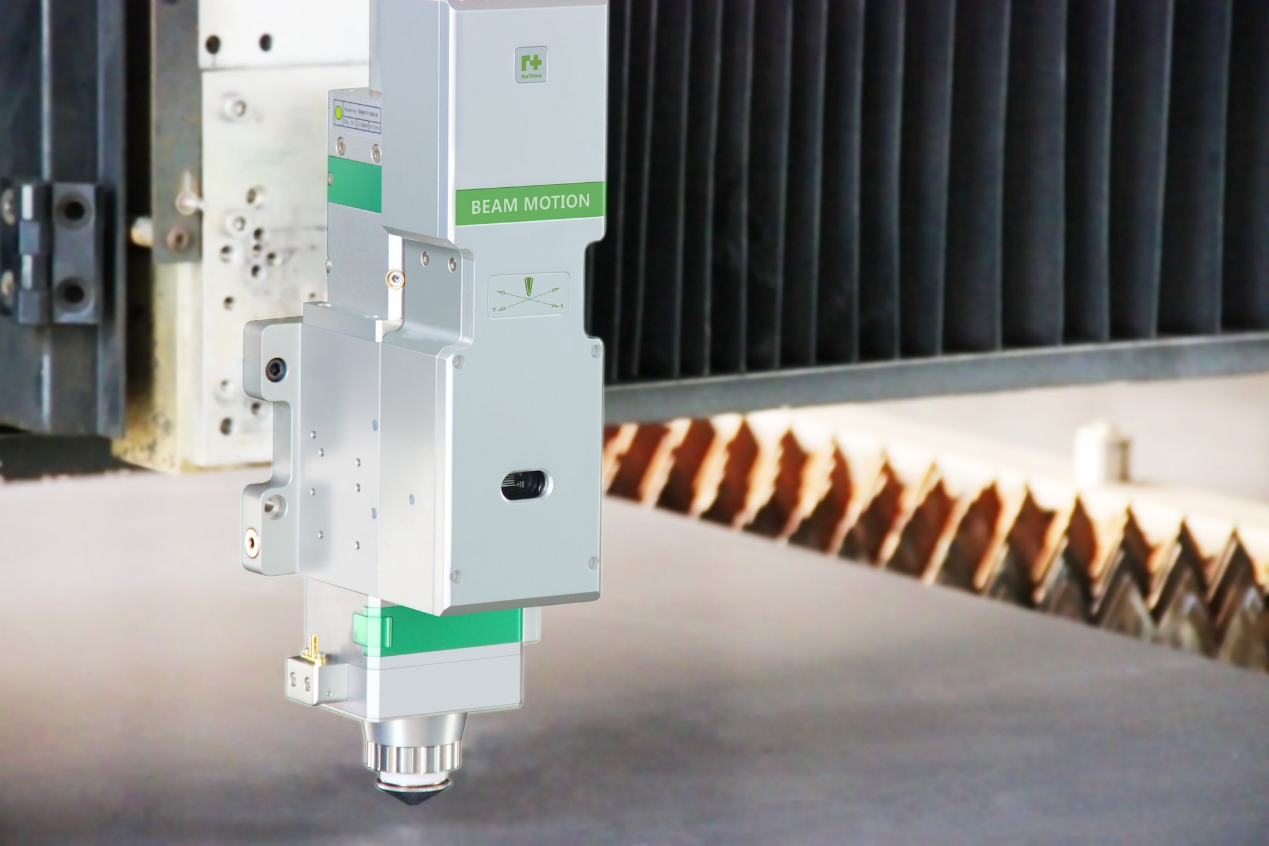

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

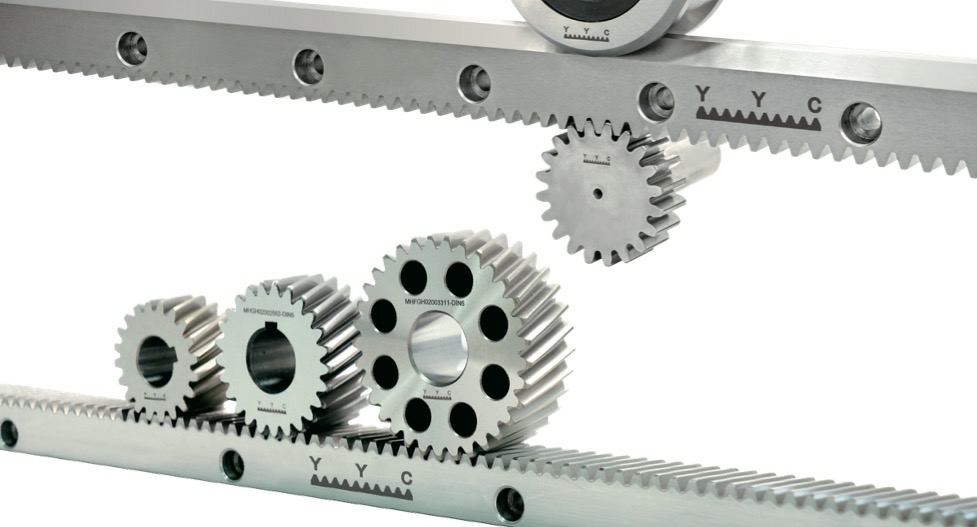

Adopts Japanese Yaskawa motor, Taiwan HIWIN guide and YYC rack gear, French motor reducer. The positioning accuracy of the machine tool is 0.03 and repositioning accuracy can be 0.01.

Do not hesitate to give us a call or drop off a message if you have any question.